If you don't see any actual holes (coloured pink/green polka) when the message pops up, I don't think you need to be concerned. However Cura automatically closes all holes less than 5 micron wide when slicing, and I've seen before that the detection of non-manifold meshes is more sensitive than that. The symptom of non-manifold meshes is that chunks of some layers are missing, so it's really easy to see. Some people say it's not a problem in Cura 4.6 (but some people deny that too) so downgrading might help.Īlso, are you saying I should just ignore the "not manifold" message? The model looks fine and there aren't any polka dots so I would assume its fine.Īlways check layer view first, see if anything is missing. The issue seems to trigger by opening certain dialogues or switching context, and restarting Cura also seems to help until you open such a dialogue again. There is one workaround posted by Lukapp here. You learn to recognise issues people have ) It's just that for work, the past 6 years, I spent ~3 hours per day triaging issues and this is a common one recently. So just be sure to check out Layer View before you print. But if the model is very complex you might see that some pieces are missing from the print. Quite often it guesses well if there are just small holes.

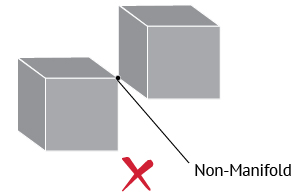

Although humans can usually gloss over small holes and guess where the inside is, a computer sees those as a problem.Ĭura will then just guess what the inside is. If there are holes in the surface or extra walls in the middle, it's ambiguous where exactly the inside of a model is. Why is this a problem for 3D printing? Because to make it physical, Cura will need to know what the inside volume is of your model.

#Meshlab fix non manifold software

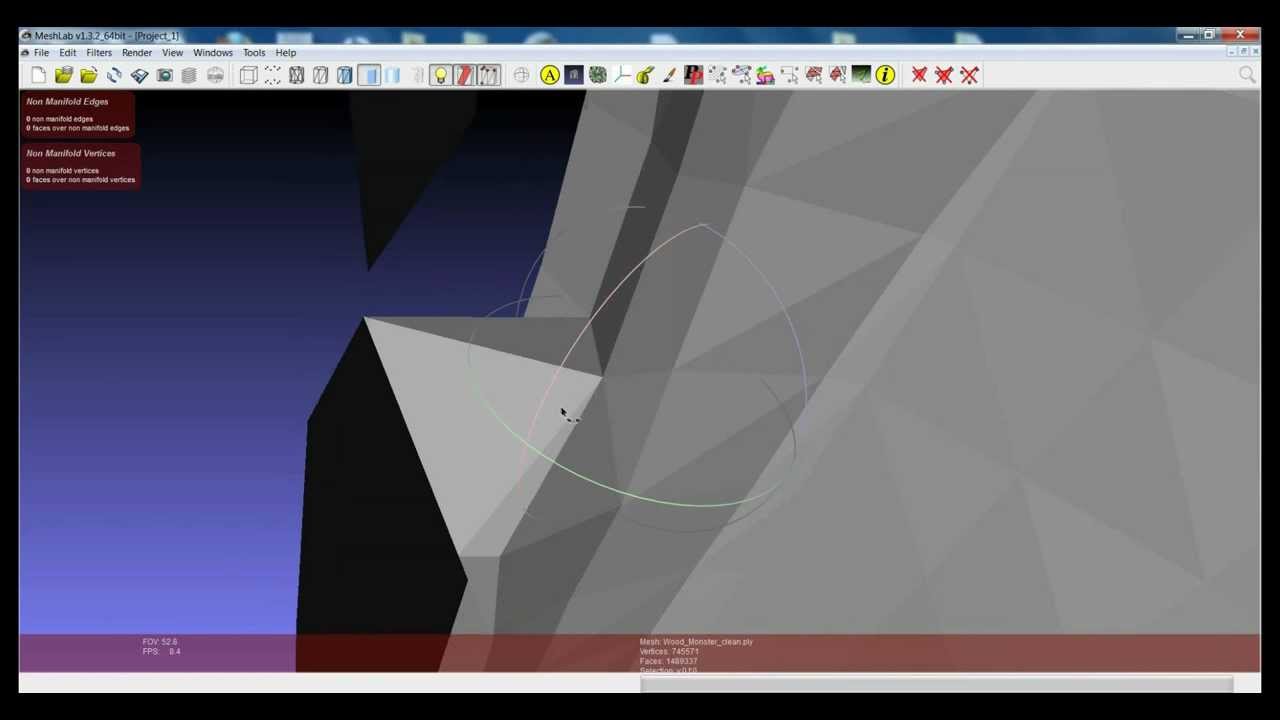

In particular SketchUp is notorious for making non-manifold meshes.Įven on Thingiverse there are a lot of 3D models that have been taken from some game or just made with bad software and those are not ideal for 3D printing. made with software designed for either of those cases.made for cinematography, because those are often just made to look nice without regard for whether the model is geometrically perfect, or.made for 3D games, because those often leave out parts that wouldn't be visible for the player to make the game more efficient, or.Models you find on the internet are not always manifold, especially if they are: It needs to be just a single continuous surface. In more human language, the consequence is that the model is watertight (no holes in the surface) and there are no extra surfaces on the inside. - // stl parameters stl_file = "model.stl" _rotate = _translate = _scale = 1 // Mold parameters // Along X axis mold_width = 50 // Along Y axis mold_height = 60 // Along Z axis mold_depth = 14 // Space between the halves mold_spacing = 3 // Lock parameters // Radius lock_size = 3 // Size difference between locks lock_difference = 0.5 // Distance from outside lock_margin = 5 main () // main //- Configures Rotating and placement //- both along the X-axis //- module main () Ĭhange model_filename to the name of the STL and configure the parameters.For an object to be "manifold" in a 3D mesh means that all edges connect exactly 2 surfaces together. Tips for Preparing a Model ¶ Making the Model Solid (No internal structures) ¶Īutodesk’s Meshmixer can be used for this process. The main cause of “non-manifoldness” are “holes” in a mesh. Manifold: A model needs to be “manifold” to possibly turn it into a mold.

Making the Model Solid (No internal structures)ġ9.

0 kommentar(er)

0 kommentar(er)